|

|||||||||

|

|

|

|

|

|

|

|

||

| ------- | ||

| - high quality aged cast iron components. - the portal is made of two columns which are mounted rigidly to the bed. At the upper end they are linked and stiffened by a heavy cross rail and support members for lager machines, the smaller ones are monoblock. - high precision guideways and trapezoidal lead screw for cross rail positioning along the columns. - hydraulic clamping & unclamping of the cross rail. - hardened steel inserts on the cross rail. |

|

|

| Top | ||

| Table and workholding support | ||

| - the table is made of special cast iron and is heavily

ribbed - table motion on the bed is either by cross roller bearings or optional hydrostatic bearing - the table is driven by a gear box and the speed is infinitely variable - in milling operation, (optional C-axis) the table is driven by means of a feed gearbox, which utilizes a duplex worm gear and hydraulic backlash compensation |

|

|

| Top | ||

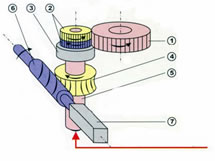

| C - axis Drive | ||

| 1. Table drive gear 2. Pinions 3. Hydraulic backlash compensation system 4. Worm gear 5. DEUBLIN type rotary fitting 6. Duplex worm shaft 7. Feed motor |

|

|

| Top | Hydraulic oil feeder line for backlash compensation | |

| Ram | ||

| - heavy duty square ram - made of laminated steel - vertical movement by means of ball screw - guideways made of hardened steel inserts - hydraulic clamping & unclamping - hydraulic counterbalance - RAM CROSS SECTION 9.8” x 9.8” |

|

|

| Top | ||

| Cross Slide | ||

| - ball screw on cross slide - hydraulic clamping and unclamping - hardened insert ways |

|

|

| Top | ||

| FEATURES: | ||

| •Machine is designed for the the machining of large and medium

sized workpieces of complex shapes •Deep RAM travel & tilting RAM •Numerous customization options available •High quality machining capability •VICKERS or REXROTH hydraulic elements •European/North American mechanical components •FANUC /SIEMENS Control •1 (optional 2) ATC with 12 tool spaces |

|

|

| Top | ||

| Top | Contact us: info@cncmachinetools.com | |